The spring 2026 semester is in full swing at Morningside University!

I am teaching Graphic Design I, Painting I, Graphic Design Internship, and Senior Art Seminar.

Teaching

The spring 2026 semester is in full swing at Morningside University!

I am teaching Graphic Design I, Painting I, Graphic Design Internship, and Senior Art Seminar.

Classes at Morningside University began earlier this week; I always enjoy meeting new students and look forward to catching up with returning ones!

This fall, I am teaching ART 103 Design, ART 210 Graphic Design I, ART 402 Advanced Studies in Art History, and ART 470 Graphic Design Internship.

As Morningside’s galleries director, I scheduled an art sale to open up our fall season in Eppley Art Gallery! I will be selling prints and ceramics, and I look forward to seeing what else other members of our community offer. It will open on Thursday, August 28th and run through Friday, September 5th on weekdays.

Sales times are a bit up in the air as it depends on when I can hire students for shifts, but should be some subset of 1-5pm. Please stop by if you’re interested, and note that we only take cash or check.

I learned yesterday that I will become a senior faculty member at Morningside University beginning next fall, as I will be promoted to full professor!

In academia, there is a ranking system which is typically: instructor → assistant professor → associate professor → [full] professor.

I served as an instructor while teaching at Louisiana State University in graduate school in 2011-2013, became an assistant professor when I was hired full-time at the University of Saint Mary in 2013, was promoted to an associate professor in 2019 after earning tenure at USM but then moving to Morningside University, and have held the rank of associate professor since then while earning tenure at Mside in 2022.

It is an honor, and one that few academics reach before their mid-40’s, so I’m pleased to have earned it at the relatively youthful age of 38!

Coming up on Tuesday, February 18th at 7pm in Morningside University’s Weikert Auditorium (on the 2nd floor of the Buhler Rohlfs building), I will be presenting in the Morningside University Humanities Speaker Series with my Clay and Fire: Exploring Raku Ceramics lecture. This event is free and open to the public, so please stop by!

Shelby Prindaville's Morningside University Humanities Speaker Series raku ceramics lecture ad for February 2025

Here are progress photos of Paper Snow (紙吹雪)! You can click on any of the thumbnails to see them larger in a sidescroll viewer. (Note that for in-process documentation, I rarely ensure a uniform lighting situation nor accurately color adjust the resulting photos like I do for the artwork photo.)

This painting was unusual for me in that I almost always start painting backgrounds before moving on to foregrounds and then going back and forth between the two until I think the piece is finished. With this painting however, I knew I didn’t want to obscure too much of the beautiful Uzurado dyed washi paper, so I started with the subject and then tested out just a cast shadow composition before adding a little ground and horizon.

In Spring 2025 here at Morningside University, I will be teaching Graphic Design I, Painting I and II, Senior Art Seminar, Graphic Design Internship, Internship in Arts Administration, and Senior Project in Arts Administration. Enrollment in Senior Art Seminar has been steadily climbing, so keep your calendars open for all the exciting senior show receptions that will be happening in April and May!

Final grades have been submitted, I was applauded for my 5-year work anniversary milestone at Morningside University’s annual holiday banquet, and supply orders for the next semester have been placed! Over winter break, I will be working on a number of studio projects in ceramics and painting. I will share more about those as they unfold.

I look forward to 2025!

Today I selected artwork for USD's Fall 2024 Student Art Exhibition and helped install the show, which will have its opening reception tomorrow (Thursday, December 12th) from 7-9pm at Cee Cee's Gallery in Vermillion, South Dakota. If you are planning on coming based on my previous post about this, note the updated time.

As long as the weather isn’t frightful, I plan to be in attendance at the reception as well - so I may see you there!

I’ve been invited to give an artist talk at the University of South Dakota (USD) in Vermillion, South Dakota on Monday, November 18th at 2pm in the Warren M. Lee Center for Fine Arts! This event is open to the public - if you’re interested in attending, here is the Facebook event page for it.

Both beforehand and afterwards, I will hold studio visits with individual students, and later in the semester will guest curate USD's Fall 2024 Student Art Exhibition, which will have its reception on Thursday, December 12th from 6-8pm at Cee Cee's Gallery in Vermillion, South Dakota.

I’m very excited to connect with the USD art students, faculty, and community in each of these ways! Many thanks to USD’s Associate Professor of Art Amber Hansen for these invitations.

My ceramics colleague Paul and I attended another Dakota Potters Supply raku ceramics workshop this past weekend! I was fortunate enough to receive partial funding from the Morningside Fall 2024 Faculty Conference Travel Fund, which allowed me to really experiment with new techniques.

We were hoping to bring three students along as well, but trimming disasters and a rescheduled athletic event took two out in advance and illness struck the third on the morning of the workshop. Fortunately, there were a bunch of other artists in attendance and Paul and I had brought quite a few pieces to finish, so we still had a lot of opportunities to learn and grow. I tried a new-to-me technique out, significantly improved in my honey raku technique, and picked up supplies to test out a method in our upcoming workshop in April that I saw another artist successfully using! I also demonstrated some techniques other artists in attendance hadn’t yet been exposed to, so there was a productive exchange of information all around.

Here are a few photos from the day itself, and once I’ve had time to photograph the pieces I made, I’ll do a series of posts on the artwork.

While I haven’t finished posting about my summer adventures, time is still progressing and the new academic year has begun! Today is the first day of classes this fall at Morningside University. I am teaching Design and Graphic Design I as well as overseeing Graphic Design Internship and Advanced Studies in Graphic Design.

It’s fun to get to see familiar and new faces, and I’m looking forward to getting to see all the new artwork my students will be making!

I just got back from another raku workshop at Dakota Potters Supply in Sioux Falls, SD! I brought along a group of faculty, alumnae, and students from Morningside University.

This workshop specifically focused on obvara and slip resist naked raku. I really like obvara, but since I just did a bunch in the fall, I only put four pieces through the obvara process and ran ten through two slip resist processes: one-step and two-step slip resist. Dakota Potters Supply had tried to troubleshoot the slip resist one-step process in advance of our workshop, but they really hadn’t figured it out so we were all experimenting and troubleshooting with our the slip resist attempts throughout the day.

I still need to edit the photos of my pieces - plus, two of them were underfired enough that Dakota Potters Supply kept them back to refire again later, so I don’t know when those might rejoin me (if they stay whole)!

Here are photos from the day of the workshop (Saturday, April 20, 2024):

I’ve been preparing for a special raku workshop I’ll be taking faculty, alumni, and students to in late April where we’ll be doing slip resist naked raku as well as obvara again. The slip resist naked raku in particular is a new challenge that is pushing me to explore outside of my comfort zone and develop my skills, as we’ve been advised that we should use terra sigillata and burnish these pieces for the best finish.

What is burnishing? Simply put, it’s when you polish the surface of the clay to a high shine. Why burnish? It is a luminous way to finish the surface of a low-fire piece of pottery that will not be receiving any glazing, spray acrylic coatings, or other surface alterations like wax or paint.

I’ve dipped my toe into burnishing before, as I tend to make very smooth pieces and have casually burnished parts of a piece while smoothing. However, I’d never really looked into burnishing before or set out to fully burnish a piece and keep its burnish post-firing.

After researching, I believe there are six main variables. Those are:

clay body

clay body wetness level

lubricant

polisher(s)

bisque temperature / cone

final firing’s temperature / cone

I also learned that any piece I’d partially burnished before automatically lost its shine during the quartz inversion and vitrification stages in a high fire, and that it’s also a waste to do with pottery that you’ll end up glazing as the glaze will take the place of the burnished surface. Good to know! Burnishing is really for low-fire, “naked” processes. (You might think to yourself that I have done some of those processes before, including obvara and saggar-fired raku. And I have! So I now want to try using burnished ceramics for those, too!)

My clay body is Chad’s Bod, which I believe is a new local mix that’s proven to handle the thermal shock of raku well but means I don’t think anyone’s published any information on how it handles burnishing. I was advised by the workshop coordinators to apply the terra sigillata to leatherhard pottery and then burnish with pantyhose, a soft cloth, or a plastic bag. I gave that a try, but then gave up quickly on the cloth/plastic bag approach and moved back to my tried and true agate tools. The terra sig began to sort of start to mix into the clay body, but I did get a very nice shine! However, once bone dry, all of those pieces lost their luster. I spent some time digging online and found out that’s to be expected, as at a microscopic level the clay surface wrinkles enough to disrupt that reflectiveness as it fully dries out. I reapplied another layer of terra sig and reburnished a couple of these pieces, but the terra sigillata began to delaminate / flake off. Upon googling, that’s also a frequent problem with this specific sequence (burnished leatherhard pottery with a terra sig layer atop when bone dry and reburnishing). I tried another lubricant I read about online, vegetable oil, for the second burnish of a couple more of these pieces in the hopes that it’d be less likely to flake off, and it seemed to reduce the delamination a bit but there were still hot spots. So my first four pieces have some minor surface irregularities.

Next, I decided to try the advice I saw online to apply the terra sig to bone dry ceramics. I did so, and that did seem to be a better solution. The terra sig seems less likely to delaminate. On one of those, I tried putting the terra sig on and letting it fully dry, then using vegetable oil to burnish; that worked out pretty well. Then I tried putting the terra sig on and burnishing it once it was mostly soaked in, and that also worked out pretty well. Since the latter is the faster method, that’s what I plan to do moving forward.

Once I troubleshot and mostly resolved the delamination / flaking issue, I refocused on getting a perfect burnish. In my mind, Magdalene Odundo’s ouevre is my gold standard for burnishing. Her handbuilt pieces have such a flawless burnish and high shine. My best pieces thus far still have some ridges and low spots… but I’m also just starting my burnishing journey!

I’ve come to believe that to get that clean a result, the piece itself needs to be flawless pre-terra-sigillata and then I need to try to ensure a perfectly even terra sig application. Easier said than done, but now that’s the next step I’ve been working on.

Amongst all of this, I was worried as I’d read that some beautifully burnished pieces lose their burnish in the bisque fire due to the quartz inversion stage and my friend Susan also witnessed that firsthand. My studio typically bisque fires to cone 08, and that’s not too far from the cone 06 to 04 temperature of our normal raku firing. I decided to risk putting my first five burnished pieces into a cone 08 bisque kiln load to see what would happen, as if they lost it there, it’s very likely they’d lose it in the raku too. I am very, very pleased to report that they kept their luster! This also means I am quite hopeful that they will be able to keep it through the raku firing processes as well.

Whew, this is getting long! I’m writing all this out for a couple of reasons. The first is that as much as I can find it frustrating at times, I deeply enjoy creative problem-solving and wanted to share a taste of such an experience with you. The second is that after spending a lot of time researching burnishing online, there are a lot of vague or contradictory pieces of advice out there. I want to provide a resource that explicitly spells out every variable I’ve used and tried so that future burnishers can easily compare notes.

So - below are my current, best burnishing techniques and I will update this post with any new insights as they come:

clay body: Chad’s Bod clay body, smoothed as perfectly as possible (but not burnished) during the forming and leatherhard clay stages using wooden ribs and plastic spreader; try to have a completely flush surface with no bumps, pits, or scratches

clay body wetness level: wait for the clay body to become bone dry

lubricant: apply terra sigillata as the lubricant because it performs well and it is whiter than the clay body which will increase the contrast of the final product; apply it carefully with a fan brush to both the interior and exterior of the piece and try not to leave any visible brush marks; brush it on continuously until you’ve put two to three layers onto the main decorative areas, and at least one onto hard-to-access interiors

polishers: after you’re finished applying the terra sigillata (when it’s not so wet as to come off on your fingers, but the bone dry pottery sucks all the moisture out very quickly so I do it pretty much immediately upon finishing application), use a combination of the plastic spreader, agate tools, needle tool, and river stone to polish, not pressing very hard and trying to go in multiple directions to catch any imperfect lower spots

bisque fire at cone 08

raku fire at cone 06 to 04 (fingers crossed!)

On the left, an unburnished Chad’s Bod bisqueware vessel. On the right, a terra sigillata burnished bisqueware piece (on this piece, I did not apply terra sigillata nor burnished the interior). Note the difference in sheen and color.

The gold-plated ring I found in recycled studio clay. It’s seen better days!

Recently, I was in the ceramics studio one morning rolling out a slab to make a few new plates. Our slab roller is permanently set to what I consider too thick (maybe a half inch?), so I always roll it out further by hand. I was rolling a plate out to about 1/4”, and what looked like a little piece of dried clay was disrupting the surface. I considered leaving it in as eventually the water in wet clay gets pulled into drier clay bits and it all melds together, but as I continued rolling it was continuing to be an issue so I decided to pick it out.

As I stuck my fingernail under and pulled, it turned out to be a way bigger mass than I’d thought… and it appeared to be metal. After rinsing, it revealed itself to be a gold ring! Well, a formerly gold-plated ring that’s been significantly banged about through at least one pug mill processing. I don’t know how long it’s been kicking around the ceramics studio - days, weeks, months, and years are all viable timelines! It’s a shared studio space and we recycle our clay, so I don’t know if we’ll ever find out more about the timeline and its owner but I’ll update if we do. My guess is a student forgot to remove their hand jewelry before throwing and didn’t notice as their ring got sucked into the clay body. The piece never came together, so they recycled it back into our studio clay ecosystem and eventually, I found it! I posted my find to Reddit, and a fellow ceramicist thinks it could be this ring.

I asked our ceramics instructor Paul and my retired colleague Susan what they’ve found in shared clay in studios, and their answers were needle tools (scary!), metal ribs, bolts, and sponges. So far I’m the only one who’s found a gold ring.

If you’re familiar with children’s and young-adult literature, you might agree that this could be a promising beginning that could lead to future magical shenanigans or inherited kingdoms!

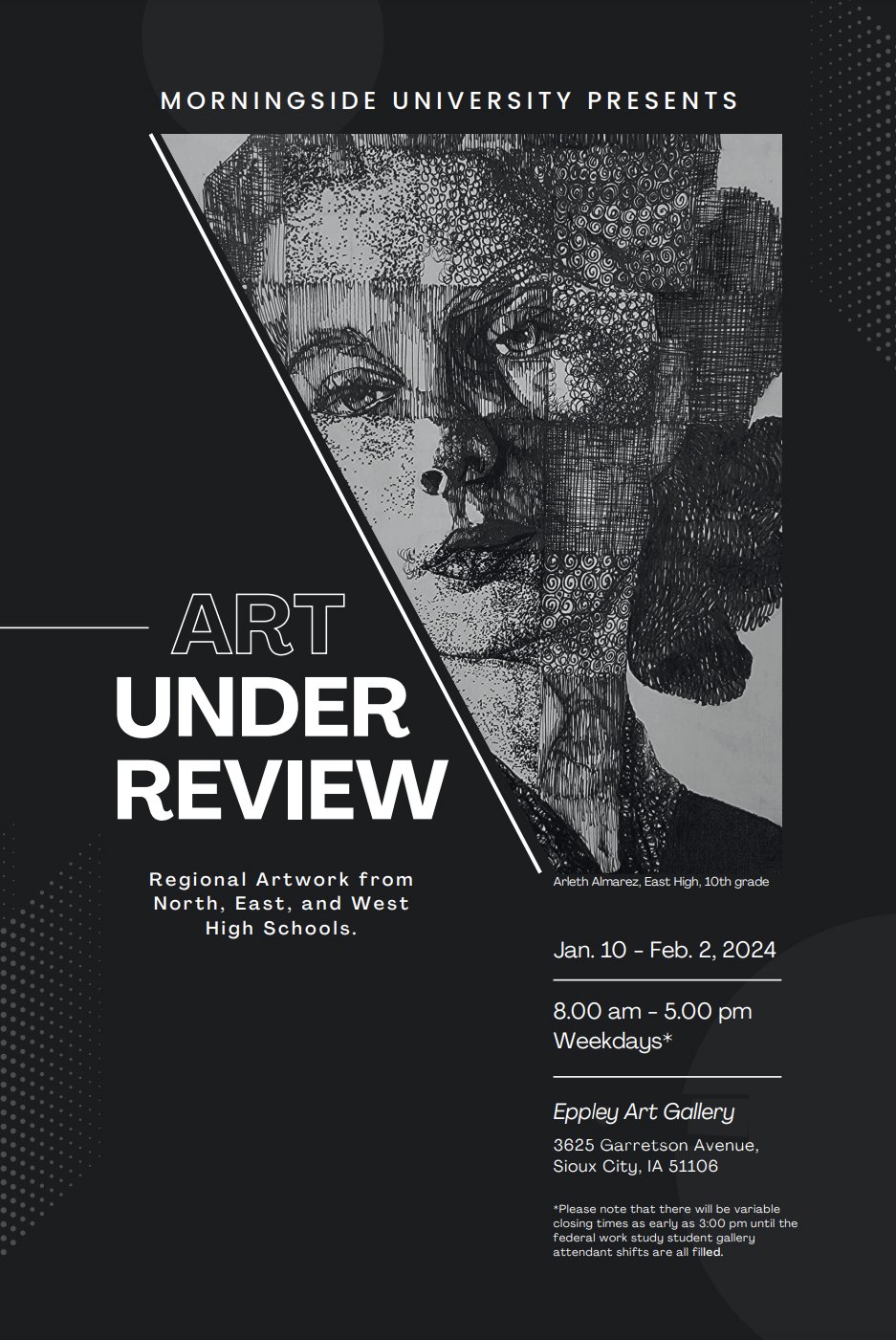

The head art teacher for the Sioux City Community School District reached out to me last year and asked if we would be willing to host a competitive art show in Morningside’s Eppley Art Gallery for three regional high schools’ artists: North, East, and West High Schools. Each high school’s art teacher would select the entries, and then I was asked to judge the pieces and award prizes as well as provide a critique of the artwork for the students.

I enthusiastically agreed! The show, Art Under Review, has been on exhibition in Eppley Art Gallery from the beginning of the spring semester on January 10. I will be announcing awards and critique feedback on January 31. The visiting student artists will also get to attend an art workshop and take a campus tour. The show will continue through February 2, 2024.

In Spring 2024, I will be teaching Graphic Design I, Painting I, Advanced Studies in Ceramics, Arts Internship, Arts Administration Internship, Senior Art Seminar, and Arts Administration Senior Project at Morningside University.

After asking about it repeatedly for three years, I successfully convinced the lovely folks over at Dakota Potters Supply to allow us to do an obvara raku workshop on October 21, 2023! Obvara is a low-fire scalding-and-sealing process wherein you create a fermented sourdough/beer bath, plunge approximately 980°C naked ceramics fresh out of the kiln into it, wait for them to start to bloom with different tan-to-brown markings, and then arrest the surface carbonization process by rinsing the pieces off in a water bath. Obvara has an even higher chance of cracking due to the extreme thermal shocks involved than non-bath raku processes.

Getting the chance to do raku is relatively rare, and many ceramists haven’t even heard of obvara, let alone had the opportunity to do it - so I’m really grateful for the experience! Joining me on the trip were Morningside faculty Paul Adamson, alumni Calissa Hanson and Deb Murakami, and students Laura Greene, Taylor Greene, and Lauren Hedlund.

In addition, I learned about honey raku from a ceramist at this year’s ArtSplash festival - it’s basically like horsehair, feather, or sugar raku surface carbonization, but with honey! I brought some along and we tried it out too - though I want to experiment with it some more at future workshops as I was so excited about the obvara opportunity that I only kept one textured plate aside for honey raku.

Here are some photos from the workshop itself, soon to be followed by pictures of my finished pieces! I applied for and was granted funding from our Faculty Development Committee to help with my costs, so I made and brought 18 pieces along this go-round - both to make up for any thermal shock victims, and because I didn’t need to apply glaze to my obvara or honey raku ceramics so I could get more processed compared to when I need to apply 1-8 layers of glaze to each piece on-site before firing (for crackle and copper glazes or ferric chloride dips). If you’ve been following my raku workshop production, 18 is about double the number of ceramics I typically aim to bring.

Time flies, and we’re starting up another school year again! This Fall 2023 I will be teaching Design, Graphic Design I, Graphic Design Internship, and Advanced Studies in Graphic Design at Morningside University. I will also be taking Intro to Japanese!

Miriam Moore’s new Sioux City Garden Club logo design!

I love to partner with community organizations in art department coursework with beneficial, real-world projects. This semester, I agreed to host a design competition within our graphic design program for the Sioux City Garden Club! Their president, La Vone Sopher, reached out to me and we worked out a plan: students in Graphic Design I and II would submit logo designs, and the club would proffer a $50 first place (and use that logo) as well as a $25 second place prize.

Students in these two courses submitted 26 designs, and there were a lot of quality options for the garden club to choose from! The board winnowed it down to six, and had the club members vote to select their first and second place designs. Graphic design and history major Miriam Moore’s logo was the winner!

I like to take on these sorts of projects - even though it invariably adds to my workload - because students get to work with actual clients, the top designers receive compensation, and all students create portfolio pieces while the winner sees their work enter the community. It also raises both the winning artists’ and our art department’s visibility… particularly when we issue press releases about the successful conclusion of the partnership!

Here’s the Morningside University press release (complete with a quote from me), which was picked up by KWIT and a KTIV television interview.

Me and one of our brand new alumni at the 2023 Morningside University graduation ceremony!

This was a special year for me, as this graduating class is the first I’ve had at Morningside University where I’ve seen them through from start to finish - it’s my fourth year here, too!

Graduation was on Saturday, May 13th, and it’s always heartwarming with a dusting of saudade. I’m excited to see my students continue to progress in their professional and personal lives, but it’s always a little sad not to have them around nearly as much as I’ve become accustomed to. New students will be arriving in the fall, though, so the cycle will begin again!