I’ve been preparing for a special raku workshop I’ll be taking faculty, alumni, and students to in late April where we’ll be doing slip resist naked raku as well as obvara again. The slip resist naked raku in particular is a new challenge that is pushing me to explore outside of my comfort zone and develop my skills, as we’ve been advised that we should use terra sigillata and burnish these pieces for the best finish.

What is burnishing? Simply put, it’s when you polish the surface of the clay to a high shine. Why burnish? It is a luminous way to finish the surface of a low-fire piece of pottery that will not be receiving any glazing, spray acrylic coatings, or other surface alterations like wax or paint.

I’ve dipped my toe into burnishing before, as I tend to make very smooth pieces and have casually burnished parts of a piece while smoothing. However, I’d never really looked into burnishing before or set out to fully burnish a piece and keep its burnish post-firing.

After researching, I believe there are six main variables. Those are:

I also learned that any piece I’d partially burnished before automatically lost its shine during the quartz inversion and vitrification stages in a high fire, and that it’s also a waste to do with pottery that you’ll end up glazing as the glaze will take the place of the burnished surface. Good to know! Burnishing is really for low-fire, “naked” processes. (You might think to yourself that I have done some of those processes before, including obvara and saggar-fired raku. And I have! So I now want to try using burnished ceramics for those, too!)

My clay body is Chad’s Bod, which I believe is a new local mix that’s proven to handle the thermal shock of raku well but means I don’t think anyone’s published any information on how it handles burnishing. I was advised by the workshop coordinators to apply the terra sigillata to leatherhard pottery and then burnish with pantyhose, a soft cloth, or a plastic bag. I gave that a try, but then gave up quickly on the cloth/plastic bag approach and moved back to my tried and true agate tools. The terra sig began to sort of start to mix into the clay body, but I did get a very nice shine! However, once bone dry, all of those pieces lost their luster. I spent some time digging online and found out that’s to be expected, as at a microscopic level the clay surface wrinkles enough to disrupt that reflectiveness as it fully dries out. I reapplied another layer of terra sig and reburnished a couple of these pieces, but the terra sigillata began to delaminate / flake off. Upon googling, that’s also a frequent problem with this specific sequence (burnished leatherhard pottery with a terra sig layer atop when bone dry and reburnishing). I tried another lubricant I read about online, vegetable oil, for the second burnish of a couple more of these pieces in the hopes that it’d be less likely to flake off, and it seemed to reduce the delamination a bit but there were still hot spots. So my first four pieces have some minor surface irregularities.

Next, I decided to try the advice I saw online to apply the terra sig to bone dry ceramics. I did so, and that did seem to be a better solution. The terra sig seems less likely to delaminate. On one of those, I tried putting the terra sig on and letting it fully dry, then using vegetable oil to burnish; that worked out pretty well. Then I tried putting the terra sig on and burnishing it once it was mostly soaked in, and that also worked out pretty well. Since the latter is the faster method, that’s what I plan to do moving forward.

Once I troubleshot and mostly resolved the delamination / flaking issue, I refocused on getting a perfect burnish. In my mind, Magdalene Odundo’s ouevre is my gold standard for burnishing. Her handbuilt pieces have such a flawless burnish and high shine. My best pieces thus far still have some ridges and low spots… but I’m also just starting my burnishing journey!

I’ve come to believe that to get that clean a result, the piece itself needs to be flawless pre-terra-sigillata and then I need to try to ensure a perfectly even terra sig application. Easier said than done, but now that’s the next step I’ve been working on.

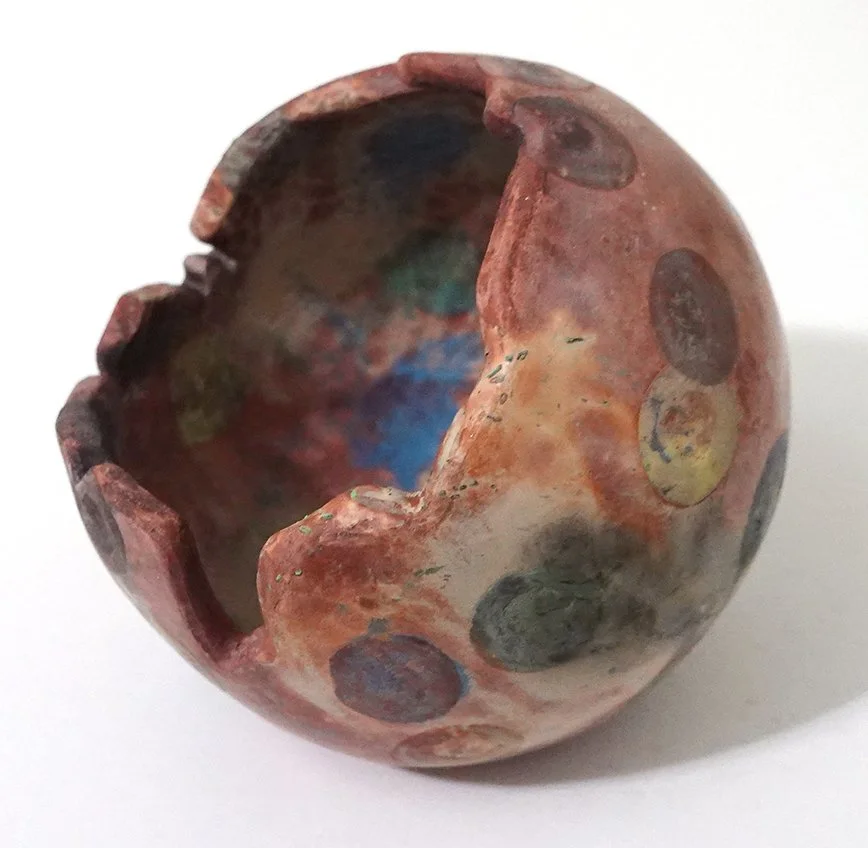

Amongst all of this, I was worried as I’d read that some beautifully burnished pieces lose their burnish in the bisque fire due to the quartz inversion stage and my friend Susan also witnessed that firsthand. My studio typically bisque fires to cone 08, and that’s not too far from the cone 06 to 04 temperature of our normal raku firing. I decided to risk putting my first five burnished pieces into a cone 08 bisque kiln load to see what would happen, as if they lost it there, it’s very likely they’d lose it in the raku too. I am very, very pleased to report that they kept their luster! This also means I am quite hopeful that they will be able to keep it through the raku firing processes as well.

Whew, this is getting long! I’m writing all this out for a couple of reasons. The first is that as much as I can find it frustrating at times, I deeply enjoy creative problem-solving and wanted to share a taste of such an experience with you. The second is that after spending a lot of time researching burnishing online, there are a lot of vague or contradictory pieces of advice out there. I want to provide a resource that explicitly spells out every variable I’ve used and tried so that future burnishers can easily compare notes.

So - below are my current, best burnishing techniques and I will update this post with any new insights as they come:

clay body: Chad’s Bod clay body, smoothed as perfectly as possible (but not burnished) during the forming and leatherhard clay stages using wooden ribs and plastic spreader; try to have a completely flush surface with no bumps, pits, or scratches

clay body wetness level: wait for the clay body to become bone dry

lubricant: apply terra sigillata as the lubricant because it performs well and it is whiter than the clay body which will increase the contrast of the final product; apply it carefully with a fan brush to both the interior and exterior of the piece and try not to leave any visible brush marks; brush it on continuously until you’ve put two to three layers onto the main decorative areas, and at least one onto hard-to-access interiors

polishers: after you’re finished applying the terra sigillata (when it’s not so wet as to come off on your fingers, but the bone dry pottery sucks all the moisture out very quickly so I do it pretty much immediately upon finishing application), use a combination of the plastic spreader, agate tools, needle tool, and river stone to polish, not pressing very hard and trying to go in multiple directions to catch any imperfect lower spots

bisque fire at cone 08

raku fire at cone 06 to 04 (fingers crossed!)