I handbuilt 15 different vessels, and as I was doing so, I thought about if I should glaze them at all, and if so, would transparent glaze from non-local sources taint the project…? I shared this quandary with friends, including my wonderful former colleague and master ceramist Susan Nelson.

After a couple of weeks mulling it over, Susan arrived at a different solution: ash glazing. I learned from her that ash can be used as a glaze, often in combination with clay to lower its melting point and smooth out the finish. I reached out to Whiterock Conservancy co-founder Liz Garst to see if I could collect some of the ash they generate, and she was kind enough to collect me a gallon bag of ash from a slash pile burn primarily composed of invasive honeysuckle bushes.

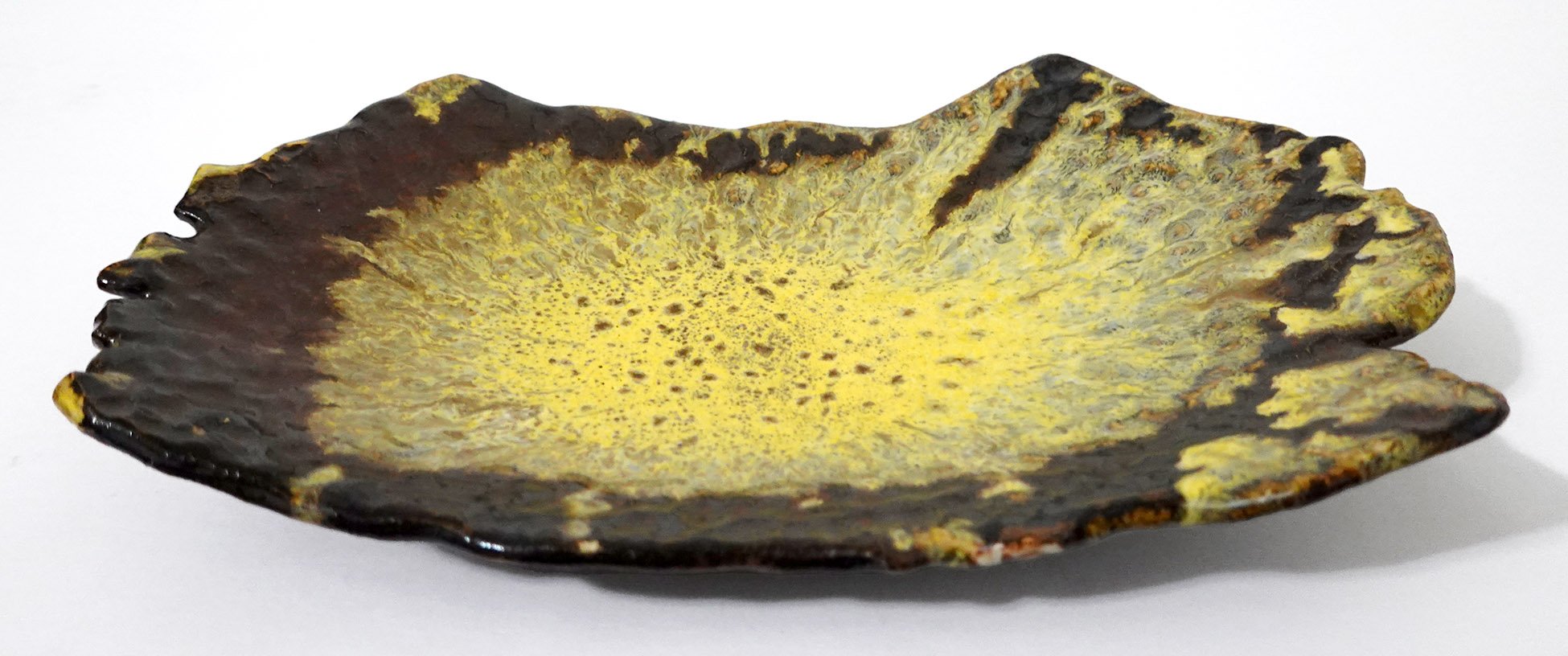

I inter-library-loaned a book on natural and ash glazes and conducted a variety of tests to determine the best ash glaze mixtures, application methods, and firing temperatures - but I also had deadlines to meet that meant I couldn’t dally too long in the experimentation phase. I eventually settled on using three ash glaze mixtures that used different proportions of clay to ash mixed with water and put 6 pieces in a Cone 8 electric kiln firing and 9 pieces in a Cone 9 gas kiln firing. Below (respectively from left to right) is a still wet raw ware handbuilt bowl, bisque-fired pieces, my work study students and I experimenting with ash glaze recipes in the ceramics studio, and ash-glazed bisque ware awaiting its glaze firing.