I’ve wanted a rock tumbler for a couple of years, but not quite enough to commit. However, I have also begun to amass broken ceramics, from raku thermal shocks to glaze fusing with kiln shelves to squirrel casualties (they try to bury nuts in my outdoor container plant collection in the fall, and repeatedly fail while digging up my plants and breaking planters in the process). Some of the broken pieces were favorites, so I just carefully collected the pieces and held onto them. (I did try to glue one planter back together, and realized that just doesn’t work well enough.)

It dawned on me that given my now multi-year interest in ceramics, I’ll have a renewable resource for the rock tumbler beyond an occasional rock harvest. I’ve beachcombed tumbled tiles before and even used them in assemblages, so I know I like the aesthetic - and, of course, the conceptual power of the push/pull between man and nature that creates them. If I make them myself out of my own handmade ceramics, I could generate enough to use the tumbled pieces for magnets or mosaics! I can also use any rejects as top dressing for plants, and I have a near infinite need there as my plant collection is unreasonably large and continuously expanding.

I began to research rock tumblers in early November. At first, I thought I’d just get a hobby one like the entry-level National Geographic model. However, I learned it doesn’t cost that much more to buy a quality version. I decided to go with Lortone as the maker. I wanted a rotary style - vibratory models also exist, but for my ceramic purposes I need the rotary tumbling action as vibrations are more helpful for surface polish while tumbling is what knocks down harsh edges.

Most rock tumbling aficionados recommend a double-barreled design, but those were sold out and I imagined it might take several months for stock to replenish given holiday demand - I didn’t want to wait that long! I considered going for a bigger volume barrel next, but then I thought about the quantity of material I have to do at any one time and in reality, it’s not that much. I eventually settled on the Lortone Model 3A tumbler. While I think I’d likely have gone with the double-barreled 33B if it’d been in stock, I also think that running two barrels at once is more for those who plan to process mostly rocks rather than ceramics. With rocks, you need to go through several stages of polish to achieve a smooth finish; with ceramics, they start with a smooth glass finish and you just need to knock the sharp sides down! I can do that in just one rough grit tumbling session.

I’ve only owned my tumbler for a few weeks, so I’m still learning, but I’m having a lot of fun and have run through my backlog of broken ceramics already! In trying to find more fodder, I’ve realized I can easily recycle my ash test tiles I created when testing ash glaze recipes for my Whiterock 41.816, -94.646 ceramic collection, so I’m still working on processing those. I love that I now have a use for otherwise already-served-their-purpose ceramics like test tiles too.

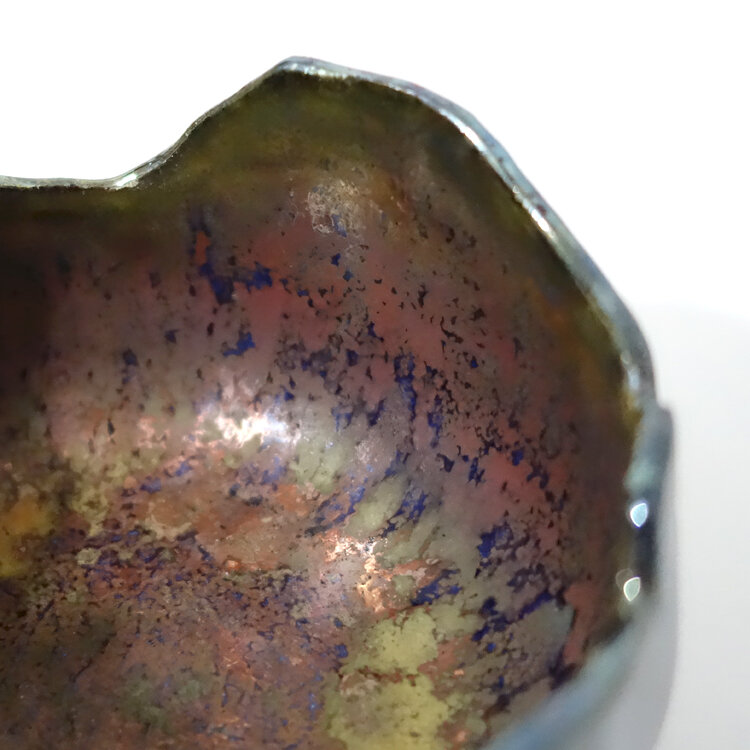

Here are some photos of one tumble from start to finish! (You can click into any of the images to see them at a larger size.)